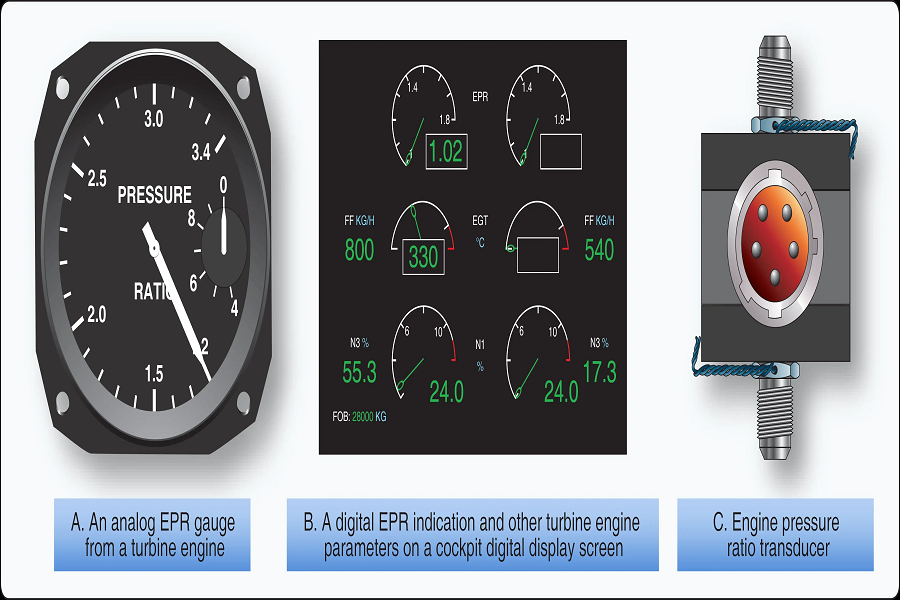

Image Source: www.aircraftsystemstech.com

Despite the fact that it’s in fact named as airplane complex strain checking, “pressure” for this situation, is somewhat of a misnomer. This is on the grounds that the airplane complex strain information isn’t about pressure however attractions.

The chambers in any airplane motor resemble an enormous pull siphon on the grounds that the chambers are continually sucking air into itself. The Guide sensor in this manner, regardless, is perusing pull not slam pneumatic stress. So out of gear power your Guide measure could show somewhere in the range of 10 and 12 inches when real strain outside is 30 inches. This implies your motors are really starving for air making a vacuum strain inside the admission complex.

As the cylinder plummets with the channel valve open, a halfway vacuum is made. It is this vacuum sucks in fuel into the admission. In this manner, more prominent the vacuum, more noteworthy the air-fuel blend and consequently more prominent the power yield from the airplane motor.

Thus, the more air-fuel blend siphoned into the chambers, the more power the motor creates and empowers us to fly higher or quicker. Presently, in the event that we measure gaseous tension in the enlistment framework, not long before it enters the airplane chambers, we will have a smart thought of how much power we can create.

In any regularly suctioned airplane motor (non super charged), the complex strain check normally has a scope of 10 to 40 in. hg. In a turbocharged motor, the cutoff points according to maker settings. Really, when the motor is closed down, the Guide ought to peruse generally equivalent to current air pressure setting.

www.researchgate.net

By and large, Guide Sensors are utilized in fuel infused airplane motors. Nowadays, the complex outright tension sensor gives moment complex strain information (as depicted above) to the motor’s electronic control unit (ECU).

The information introduced by the Guide is utilized to sort out the thickness of the air and ascertain the motor’s air mass stream rate. These figures thus assist the pilot with deciding the expected fuel blend for the most ideal (or conservative) burning. This helps resolve the start timing.

On the other hand, fuel-infused motor can likewise utilize the mass wind current sensor (MAF sensor) to distinguish the admission wind stream. In most normally suctioned motors, there is both of the over two. In constrained enlistment motor nonetheless, both will more often than not be conveyed. Normally the MAF sensor is stopped on the admission plot pre-super while the Complex Tension Sensor is introduced on the charge pipe prompting the choke body.

A less popular reality is that the airplane’s Guide sensor information can without much of a stretch be switched over completely to air mass information utilizing the speed-thickness strategy. For this, the air temperature and motor speed in RPM Sensor are utilized.

Ordinarily, current EDM’s utilization Guide sensor information for on-board diagnostics (EBD), to test the usefulness of the fumes gas